Customized research and development for aviation baggage tags to support the composite demand of three-tier products;

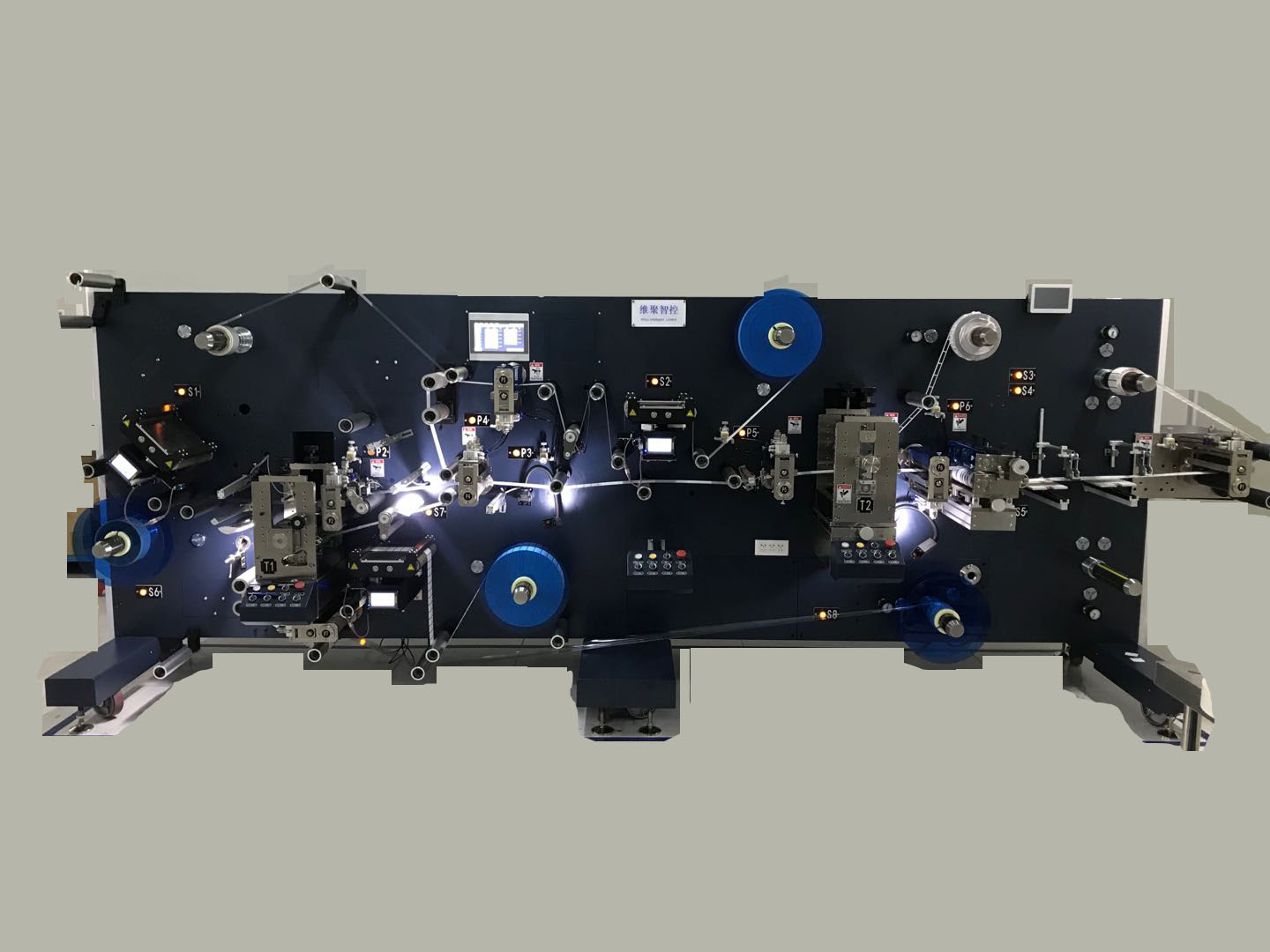

Support single-roll four-row Inlay reposting and die-cutting functions at the same time;

Fast benchmarking debugging mode, stable production speed 50m/min, maximum production speed 75m/min;

The equipment capacity is about 20-30% better than foreign high-speed equipment, and about 80%-120% better than domestic equipment, and the finished product yield rate is ≥99.97%;

Support raw material roll diameter ≤800mm, finished product winding adopts slip shaft method, winding multiple rows of products at one time;

Equipped with Inlay online detection, elimination, and standard supplement functions;

Equipped with on-line inspection of back-end finished products and inkjet function of bad mark;

Equipped with functions of automatic winding and changing of finished products to improve production efficiency;

2. Wide applicability

Three groups of die-cutting stations, the front group of die-cutting stations supports Inlay filling layer die-cutting requirements;

The latter two sets of die-cutting stations realize automatic tracking and independent multi-channel die-cutting requirements;

The die-cutting station supports industry common molds, which are interchangeable and help users save costs;

The unique reposting structure has a wider scope of application to the width and jump distance of INLAY;

3. Fast and flexible tuning structure

Many production scenarios such as die-cutting, gluing, unwinding, and console adopt humanized design to improve ease of use and accelerate productivity;

Reserve the installation location of the gluing mechanism, and the gluing function can be added later according to the needs;

The auxiliary shaft unwinding is equipped with an independent correction and receiving platform mechanism;

The operating position adopts multiple groups of independent operating tables, which is convenient to operate;

Independent finished product slitting mechanism can increase production capacity while reducing operation time;

4. Abundant expansion capabilities

Optional visual inspection and other extended functions;