RFID technology has become an important technical support for improving efficiency and reducing labor costs in all walks of life because of its long-distance reading ability, batch reading ability, data reading and writing and obstacle reading ability.

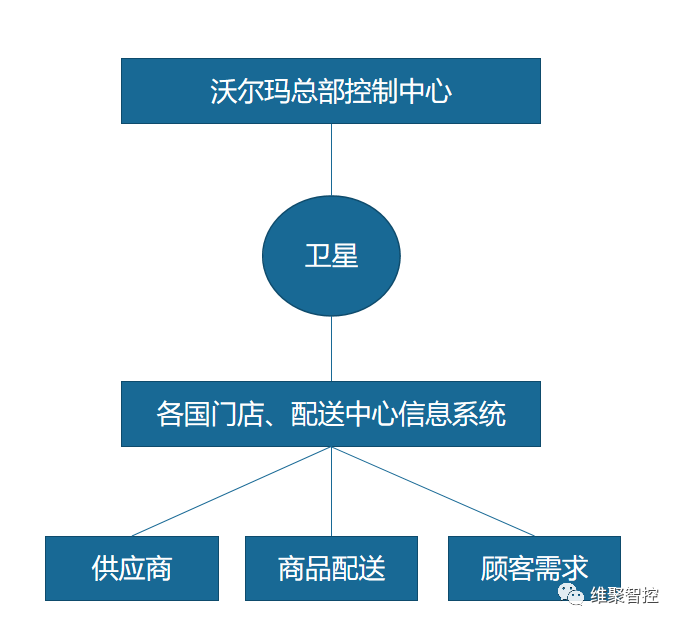

RFID can not only greatly save labor costs, but also has an irreplaceable role in improving efficiency. It is no longer a dream to know the world's battle situation in every second. With the rapid collection capability of RFID, the information system can capture the goods circulation situation in warehouses and stores around the world in real time. Combined with big data analysis, it is possible to quickly analyze and judge the purchase behavior of consumers, so as to provide rapid adjustment of theoretical data support for the strategic layout of enterprises.

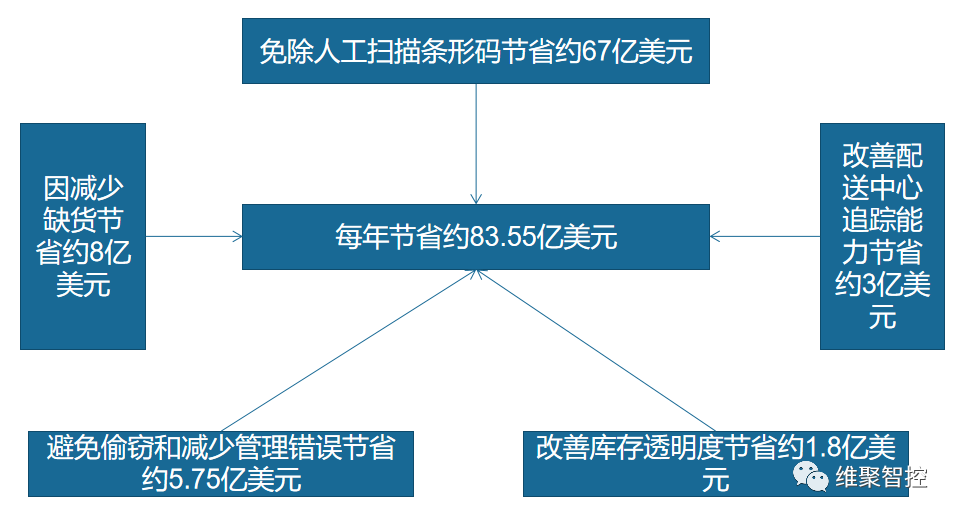

As a global retail giant, Wal-Mart has already introduced RFID into its supply chain system as early as 2003, and has gained huge benefits as a result. According to estimates by a retail analyst at Sanford C Bernstein, Wal-Mart saves approximately US$8.355 billion in costs brought about by the application of RFID technology each year, most of which are labor costs saved by not having to manually check product barcodes.

In June 2003, Wal-Mart formally required its top 100 suppliers to unconditionally use RFID tags on the pallets and containers they supply since January 2005. In August 2003, Wal-Mart made another request, requiring all its suppliers to unconditionally use RFID tags on their supply pallets and containers starting in January 2006. This indicates that the laser scanner + bar code mode that followed Wal-Mart's Southern and Northern Wars will gradually fade out, and Wal-Mart's RFID era has officially begun.

Before the formal implementation of RFID technology, Wal-Mart analyzed the supply chain process and conducted technical tests on two key points. The first key point is the distribution center, which mainly solves the problem of transparency. When the supplier’s goods enter the distribution center, the reader placed on the gate reads the RFID tag on the pallet or box to obtain the product and its circulation information. , And carry out warehousing management. When the pallet or box leaves the distribution center, another set of readers will read and record the commodity and its circulation data; another key point is retail stores, including goods entering retail stores, including goods entering retail For the management and shelf management of the store's backyard, it is necessary to set up a set of readers to record product information. Process analysis and technical testing can verify the rationality of existing processes, and calculate the return on investment of implementing RFID technology to verify the feasibility of applying RFID technology.

In April 2004, Wal-Mart began to cooperate with eight major suppliers (Gillette, HP, Johnson, Kimberly-Clark, KraftFooxls, estle Purina PetCare Company, Procter&Gamble, and Unilever) to pilot RFID technology in one distribution center and seven retail stores. plan. At the beginning of 2006, Wal-Mart decided to expand the scope of RFID trials and extend RFID applications to its 1,000 retail stores.

The supplier sorts the goods according to the orders sent by the distribution center and delivers them. When the goods pass through the Wal-Mart distribution center's receiving port, the RFID reader will automatically complete the inventory and enter the data into the virtual private office network (VPN) of the distribution center. The goods are unloaded and sent directly to the conveyor belt. The automatic equipment of the distribution center puts the goods in designated warehouses or sorts and distributes the goods according to the types and quantities of goods required by the retail stores, and then directly crosses the warehouse for distribution without manual adjustment of the orientation of the goods. When the product leaves the distribution center, another set of readers reads the product and its circulation data and enters it into the VPN. When goods are sent to various stores, GPS positioning system or RFID monitoring points set up along the way can be used to accurately understand the location and integrity of the goods, so as to accurately predict the arrival time. After arriving at the store, the truck directly drives through the RFID reader installed at the receiving port, and the goods are counted, either directly on the shelf or temporarily stored in the store warehouse. The inventory information in the store database is also updated in the VPN. As the products continue to be sold, smart RFID readers installed on the shelves can automatically remind the clerk to replenish the goods.

The merchandise placed randomly due to the customer's change of purchase decision can also be easily found by the RFID reader covering the entire store and classified by the clerk. After the customer purchases, they only need to pass the cart through the aisle equipped with RFID readers, and the statistics of the goods will be automatically completed.

General customers can choose traditional settlement methods such as cash, credit card, WeChat, and Alipay. For goods using RFID tags, they can use the face recognition system to realize unmanned payment for goods. The customer only needs to enter the payment area with the RFID tag, the system automatically senses the type and quantity of the product, calculates the amount, and then completes the payment through face recognition.